Why use RYDLYME When Boiler Cleaning?

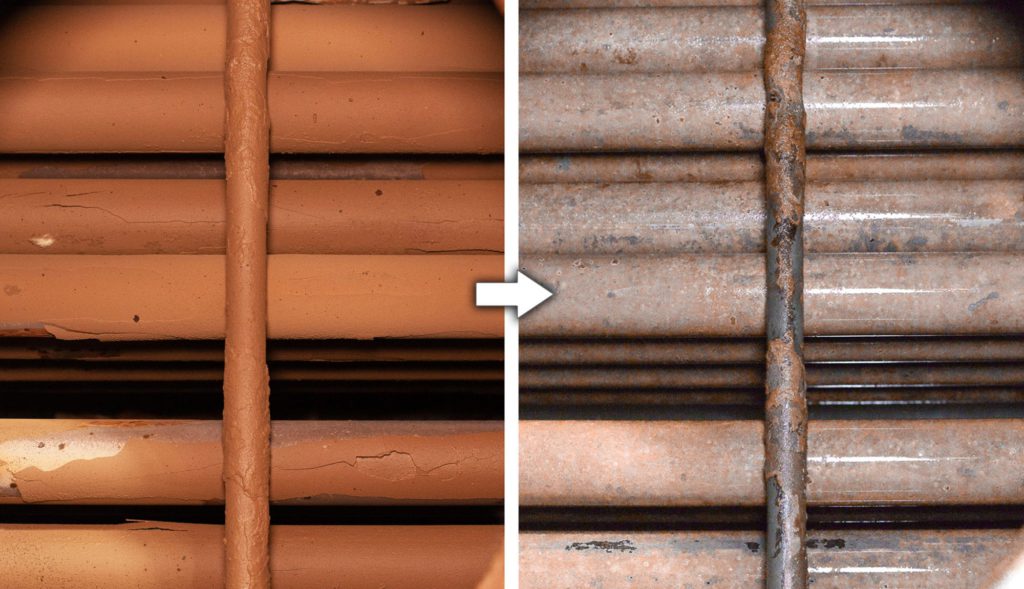

RYDLYME is the perfect tool for dissolving these deposits that rob efficiency and dramatically increase your fuel consumption. An annual RYDLYME cleaning will dissolve the calcium, magnesium, rust, and other deposits into a solution without harming the metallurgy or components within your boiler. RYDLYME is non-hazardous to the personnel who perform the cleaning and disposal is simple upon completion of the cleaning; as RYDLYME is biodegradable.

Our biodegradable and innovative descaler, RYDLYME, is the universal product of choice for boiler scale removal. Besides avoiding boiler failures, with RYDLYME you regain original design steam output, efficiency, and reliability! RYDLYME cleaning the waterside on a regular basis will improve the boiler’s technical and economic performance.

As long as you have spent the time and money on tracking tube failures, boiler inspections, and general boiler conditions, now is the time to purchase RYDLYME to maintain the water side of your boiler in peak operating condition.

What is a Boiler?

A boiler is an encased vessel that provides a means for combustion heat to be transferred into water until it becomes heated water or steam. The hot water or steam is then usable for transferring the heat to a process. This is a very efficient means for transferring heat for a process, however, over time minerals from feed water deposit onto the heat transfer surface and begin to obstruct the efficiency and increase operating costs.

Boilers represent the “heart” of many institutions including airports, condominiums, dry cleaners, ethanol production, factories, food companies, general industry, hospitals, hotels, housing authorities, medical centers, office buildings, power utilities, schools, shopping malls, and any other locations where hot water or steam is an essential part of the operation.

RYDLYME Features:

- Biodegradable

- Dissolves 2.2 lbs of scale per gallon of RYDLYME

- NSF/ANSI 60 certified

- Non-corrosive and safe for personnel

Basic Boiler Cleaning Procedure:

- Shut down the boiler.

- Blow down with pressure still on.

- Drain and flush the unit.

- Close the steam valve.

- Add RYDLYME descaler, and then top off with water.

- Circulate through the drain or low point and return from the pressure relief valve or high point of the boiler back to a vented container.

- Circulate for 4-8 hours depending on volume.

- Open the steam valve.

- Drain, flush, re-fill, and start the unit back up.

For more detailed instructions, call Apex Engineering Products today for a free quote at 630-820-8888 or download our boiler cleaning brochure here!