Chiller Cleaning

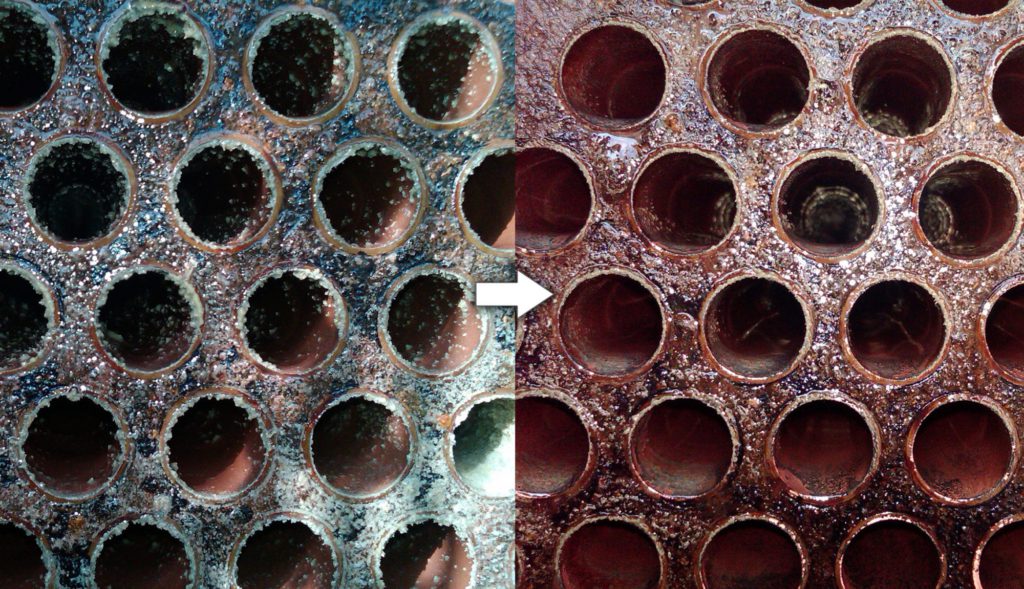

Chillers, condensers, and even cooling/chiller towers require maintenance due to the harsh mineral deposits such as calcium, lime, mud, and rust that rob heat transfer efficiency. For instance, most major manufacturers of chiller equipment generally design chillers to operate with a maximum “thermal resistance” or “fouling factor” of 0.0005 inches of buildup.

As a result, with only 0.0360 inches (about 1/32”) of deposit corresponds to an increase in energy costs of over 30%! Now ask yourself, “Can I afford not to do a RYDLYME descaler cleaning on the chiller”?

Chiller Cleaning Procedure using RYDLYME:

When isolating and cleaning the barrel on a tube chiller, chiller tower, or cooling chiller, RYDLYME descaler will circulate through the waterside and completely dissolve the scale into a liquid suspension (like sugar in coffee), easily cleaning the hard-to-reach areas such as tube enhancements.

Typically, cleanings can be accomplished in 4-6 hours depending on the severity of the scale and volume of the barrel. RYDLYME descaler can even be circulated via a cooling tower to eliminate the need to shut down the system!

Preventative maintenance cleanings with RYDLYME descaler will ensure optimal efficiency, bringing approach temperatures and pressures down to “as designed” specifications, AND will help extend the life of the equipment.

For more detailed instructions, call Apex Engineering Products and talk to our knowledgable technicians today for a free quote at 630-820-8888!