Data Center Cooling Maintenance

Keeping Data Center Cooling Systems Clean

Data center cooling maintenance is a necessity to keep servers and equipment cool. Data centers use 3% of the total electricity, requiring roughly 34 giant (500-megawatt) coal-powered plants – that’s nearly 40% more than the entire United Kingdom! According to this Forbes article, this energy consumption will double every 4 years.

This energy consumption is used throughout the plant in IT, facilities, and day-to-day operations. The facilities portion will focus on cooling the servers and hardware that stores data and information. Due to all of this energy, a massive amount of heat is produced. Servers and heat do not mix well – in fact, too much heat around a server and its components will cause the equipment to run slowly, incorrectly, or ultimately destroy it.

A common way to cool data centers and keep them running efficiently is by utilizing cooling towers and chillers.

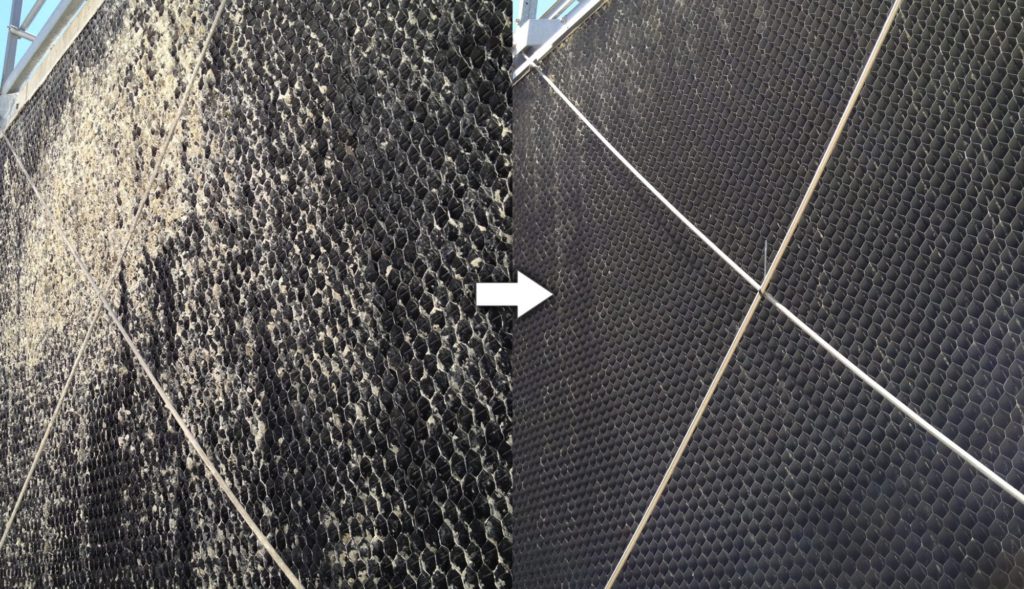

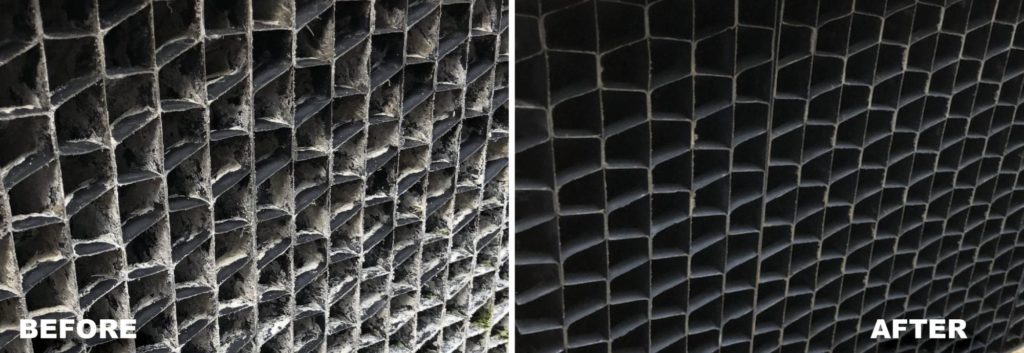

However, just like servers, this equipment needs preventative maintenance and upkeep. One of the main culprits is scale build-up on the cooling tower fill/basin and the chiller tubes.

What is a Cooling Tower’s Purpose?

The basic principle of a cooling tower is to cool the water that has picked up heat generated by equipment within the facility such as servers and hardware. The operation begins in the tower basin where the cooled water is pumped out into the facility and utilized for cooling the equipment on the tower system such as chillers. As the equipment is cooled, the water picks up the heat and returns to the top of the cooling tower. The hot water is distributed onto a hot deck or through the sprayer nozzles that evenly distribute it over the tower fill media. The tower fill media is designed to increase surface area, as well as contact time between air and water. This enhances evaporation and allows further cooling of the tower water. The water then falls into the tower basin where it is then pumped back into the facility continuing to cool the equipment.

Scaling with a cooling tower can restrict the water distribution spray nozzles, reduce the water flow through the openings of a hot deck and restrict the airflow with the tower. All of these conditions will result in diminished cooling capacity and inefficient operation of the associated equipment on the cooling tower system. Scale accumulation is detrimental in data centers as it can cause servers to overheat which leads to downtime and revenue loss.

Chiller Maintenance with RYDLYME

RYDLYME is an excellent choice for cleaning water-formed deposits from chillers. RYDLYME, will help you rid your equipment of scale deposits and have them working at top efficiency in just hours.

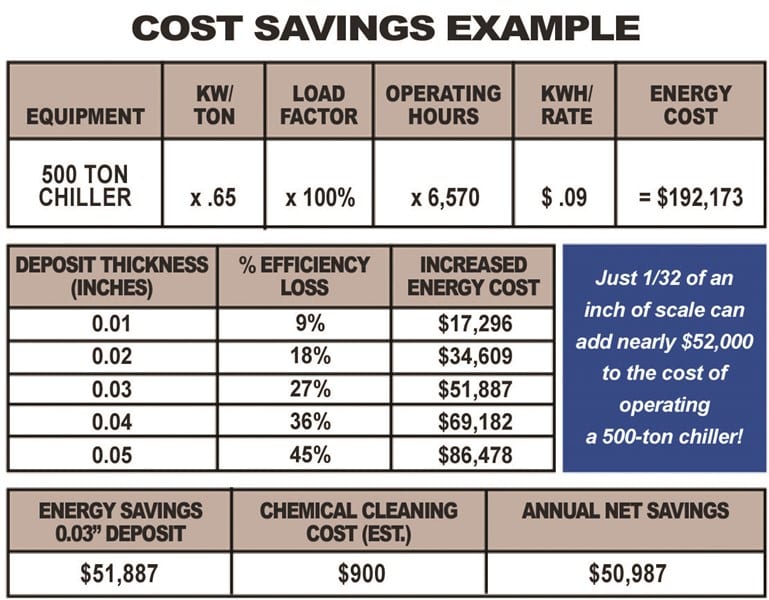

Whenever there is a deposit of any type on a heat transfer surface, it retards heat transfer. This is referred to as “thermal resistance” and it requires a corresponding increase in energy to overcome it. Major manufacturers of air conditioning equipment generally design chillers to operate at a maximum “thermal resistance” or “fouling factor” of 0.0005. As a result, with only 0.036 inches (about 1/32”) of deposit corresponds to an increase in energy costs of over 30%!

This 30% increase in costs relates to a hardness scale (calcium carbonate) deposit. Iron deposits (same thickness) are greater insulators and therefore have lower heat transfer coefficients. The actual heat transfer coefficient of a fouling/deposit (scale, lime, corrosion products, dirt, silt) depends on what it is. Certainly, any fouling/deposit contributing a fouling factor (thermal resistance) will increase electrical consumption and decrease efficiency.

The increase in electrical energy takes place in the compressor. Scale deposits increase the resistance to heat transfer, and in the condenser higher refrigerant gas temperatures will result. Higher refrigerant gas temperatures mean higher gas pressures, which require greater energy to compress the refrigerant. Therefore, there is an increase in electrical power to operate the compressor. Data centers already use an enormous amount of energy, preventative maintenance on equipment such as chillers will greatly reduce the amount of energy required to operate a chiller’s compressor due to the removal of scale on the water side of the chiller tubes.

Minimizing such potential energy losses requires ongoing, daily monitoring of KW consumed per ton of refrigerant/air conditioning being generated. The purpose is to recognize inefficient operation and determine where the problem is and fix it. Each day of inefficient operation means excess energy expenditures. Fortunately, RYDLYME dissolves the toughest water-formed deposits from virtually any type of water-heated, cooled, or operated equipment.

RYDLYME FEATURES:

- Biodegradable

- Dissolves 2.2 lbs of scale per gallon of RYDLYME

- NSF/ANSI 60 certified

- Non-corrosive and safe for personnel