What is struvite?

Struvite buildup is a common problem in wastewater treatment plants, and can cause serious issues such as reduced efficiency, increased maintenance costs, and even equipment failure. Struvite, a mineral deposit composed of magnesium, ammonium, and phosphate, can form in pipes, pumps, and other equipment, clogging them and reducing their effectiveness.

Struvite removal with RYDLYME Biodegradable Descaler

Traditionally, harsh chemicals or physical methods have been used to remove struvite from wastewater treatment equipment, but these methods can be time-consuming, expensive, and harmful to the environment and workers. However, there is now a safe and effective solution: RYDLYME Biodegradable Descaler.

What is RYDLYME?

RYDLYME Descaler is a powerful and eco-friendly solution that can effectively dissolve struvite and other mineral deposits in a fast and safe manner. It is specifically designed for use in wastewater treatment plants and other industrial applications, and has been proven to be more effective and faster-acting than competitors.

What is the RYDLYME advantage?

Unlike harsh chemicals, RYDLYME Descaler is biodegradable and safe for the environment, workers, and equipment. RYDLYME Descaler is non-corrosive and can be safely used on all types of materials, including stainless steel, copper, and PVC. The fast-acting formula of RYDLYME Descaler means that it can dissolve struvite and other mineral deposits quickly, reducing downtime and maintenance costs. In addition, RYDLYME Descaler can be used in a wide range of applications, from wastewater treatment plants to food processing facilities.

Tested and true

RYDLYME Descaler has been tested and proven to be a superior product for struvite removal in wastewater treatment plants and animal rendering plants. Its effectiveness and safety make it the top choice for those looking to remove struvite buildup from their equipment and systems. If you’re experiencing issues with struvite buildup in your wastewater treatment plant or animal rendering plant, RYDLYME Biodegradable Descaler is the solution you need. Its fast-acting, safe, and effective formula will dissolve struvite and other mineral deposits quickly and efficiently, reducing downtime and maintenance costs.

Struvite Removal with RYDLYME

RYDLYME is extremely effective in struvite removal from piping and other affected equipment in wastewater treatment plants. The amount of RYDLYME required will be dependent on the severity of the struvite accumulation and the volume of the system to be cleaned. Please see this video for circulation and this video for static cleaning.

Struvite removal RYDLYME ratio

Typically, RYDLYME will be applied at 50-100% depending on the thickness of the struvite deposits to be removed. The preferred method of application is to circulate the RYDLYME solution through the pipe or equipment, but it can also be effective when utilized in a static or fill-and-soak application.

How to Remove Struvite from Wastewater Pipes

Apex highly recommends that, prior to cleaning, you contact us for technical assistance in determining the best dilution and method for removing your struvite scale deposits. For more information on how to remove struvite, click here.

- Obtain struvite deposit for testing with RYDLYME to confirm adequate concentration to dissolve struvite (typically 50-100%). Note the severity of struvite build-up. Obtain the current water volume of the struvite infected system as well as the designed water volume.

- To set up a circulation, connect the circulating pump inlet to the vented container via a hose.

- Run another hose from the pump outlet to the lowest accessible point of the struvite-infected system.

- Run another hose from the highest accessible point of the struvite infected system back to the vented circulating container.

- Add the prescribed amount of RYDLYME to the circulating container and turn on the pump to begin dissolving the struvite. Add water to the solution until a complete circuit is obtained.

- Continue circulation for 6-12 hours depending on struvite severity and volume of the system. Hourly monitor the RYDLYME solution to determine the endpoint. If RYDLYME is neutralized prior to the prescribed circulating duration, then more RYDLYME should be added in order to remove the remaining struvite. (See “Testing the Effectiveness of RYDLYME”)

- Upon completion of the struvite cleaning, rinse the system with clean water to remove any insoluble materials that may have been released from the struvite deposit.

- Return the system to service.

RYDLYME Features:

- Biodegradable

- Dissolves 2.2 lbs of scale per gallon of RYDLYME

- NSF/ANSI 60 certified

- Non-hazardous, non-corrosive and safe for personnel

What is Struvite?

Struvite is a naturally occurring crystal of magnesium, ammonium, and phosphate. A primary concern at wastewater treatment plants, particularly after anaerobic digesters release ammonium and phosphate from waste material that crystalizes into concrete-like deposits that can form on the downstream system components.

How does struvite form?

The formation occurs because you have magnesium from hard water, ammonia as a byproduct of urea and urine, and phosphate from the organic matter being processed, coming together in the plant’s system to form crystals that can deposit on pipe walls as well as on other components of the treatment system.

Struvite Removal Case Studies

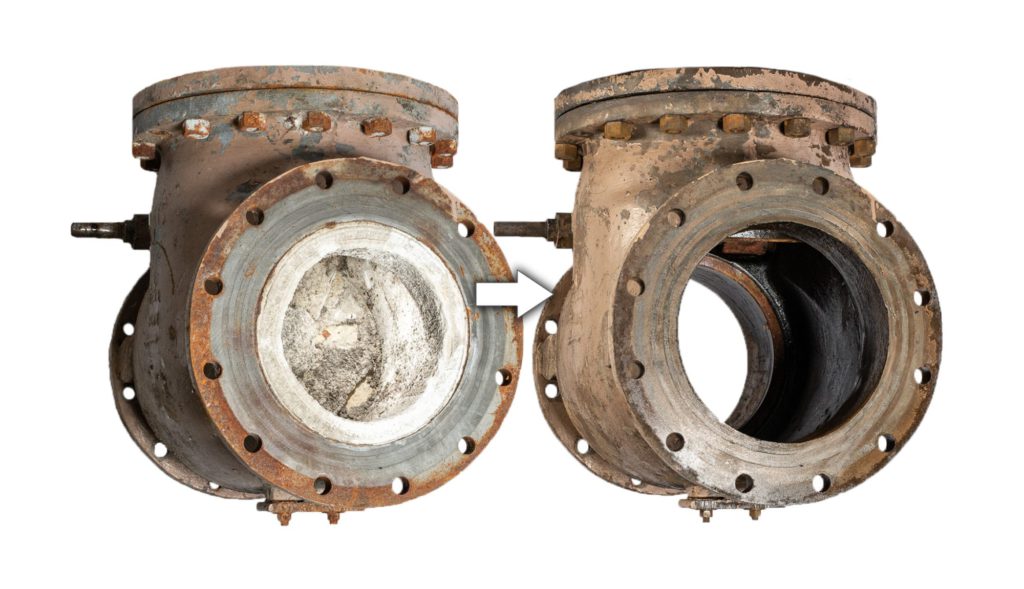

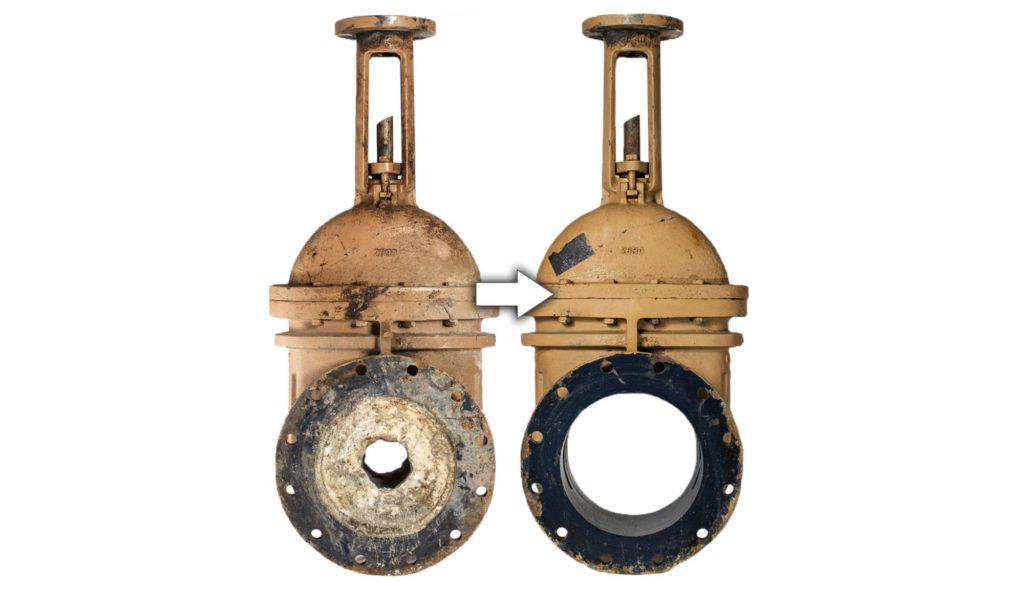

Wastewater lift station pumps, valves and piping were severely clogged with struvite deposits. Hydroblasting for days achieved no results.

Thick deposits of struvite had accumulated on numerous centrifuges at a district wastewater treatment plant.