Cooling Tower Cleaning

Cooling tower cleaning is made easy with RYDLYME Biodegradable Descaler. RYDLYME is simply circulated through the cooling tower removing mineral and scale build-up in a safe and timely manner.

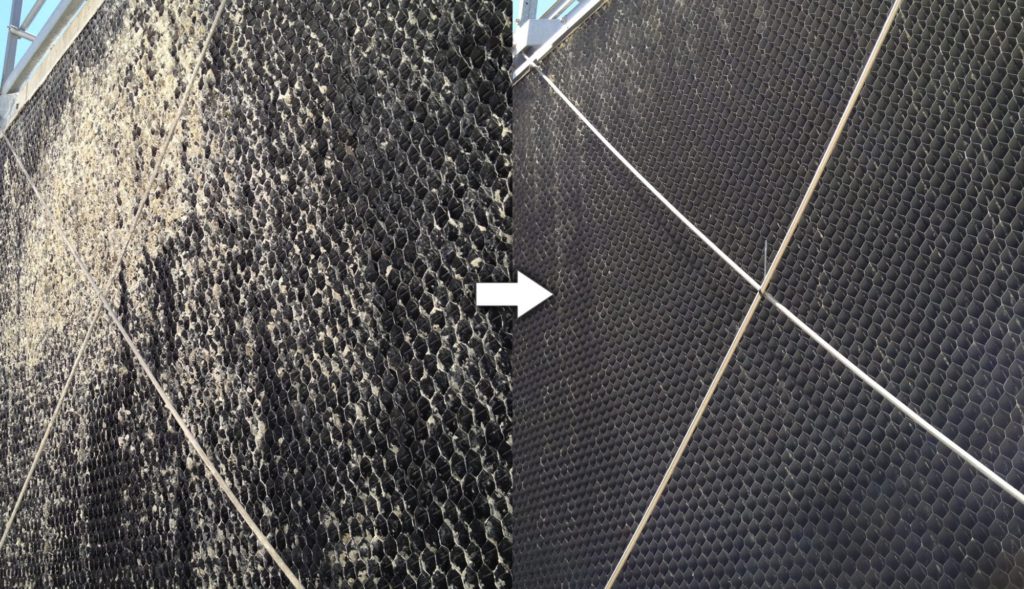

Scaling within a cooling tower can restrict the water distribution of spray nozzles, reduce the water flow through the openings of a hot deck and restrict the airflow within the tower. All of these conditions will result in diminished cooling capacity and inefficient operation of the associated equipment on the cooling tower system.

Cooling Tower Cleaning Procedure using RYDLYME:

Adding RYDLYME to the cooling tower basin allows the tower’s transfer pump to circulate the solution throughout the entire cooling system while in operation. Cooling tower cleaning with RYDLYME can all be accommodated during the normal operation of the cooling tower without shutdown! It is imperative when calculating the required amount of RYDLYME needed for a cooling tower system to include enough RYDLYME for the equipment load of the tower. This prevents the spread of Legionnaires’ Disease.

How to clean a cooling tower system:

- Close the make-up water valve to the tower basin.

- Turn off all chemical or non-chemical water treatment, conductivity meters, and pH meters.

- It is recommended that all loose water scale, lime, mud, rust, and other foreign matter be manually removed from the tower basin prior to starting the cleaning.

- Lower the water level in the tower basin to a point where the pump can maintain circulation without cavitation and close the bleed-off valve.

- It is recommended that the fans be turned off during the cleaning.

- Determine the proper amount of RYDLYME to be added to the system. Please note that the amounts recommended in the chart are just the guidelines and that your application may require 2-4 times the chart amount, depending on the severity of the deposit build-up in your system.

- To minimize excessive foaming, you may now slowly add the required amount of RYDLYME to the tower basin.

- The bubbling and foaming you will observe is a natural reaction of the RYDLYME dissolving the water-formed mineral deposits within the system.

- Once the RYDLYME is in the tower system, allow it to circulate. Start charting your pH readings or performing calcium spot tests to measure the effectiveness of the RYDLYME solution during the cleaning (“Testing the Effectiveness” is available at our website or contact us directly for a copy). If the RYDLYME cleaning solution expends prior to the completion of the recommended circulation time, there is more scale in the system. It is recommended that you repeat steps 6-9 to complete the cleaning.

- It is recommended that the RYDLYME cleaning solution be cycled out of the system to prepare it for normal operation. At this time, strainers should also be removed, inspected, and cleaned as well.

Once the cleaning material has been cycled from the tower system, turn your conductivity, pH meters, or any other equipment back on. Return the make-up water and bleed-off valves per the manufacturer’s recommendations. Lastly, resume normal system operation.

For more detailed instructions, call Apex Engineering Products today for a free quote at 630-820-8888 or download our cooling tower brochure here!

RYDLYME FEATURES:

- Biodegradable

- Dissolves 2.2 lbs of scale per gallon of RYDLYME

- NSF/ANSI 60 certified

- Non-corrosive and safe for personnel

What does a Cooling Tower Do?

The basic principle of a cooling tower is to cool the water that has picked up heat generated by equipment within the facility. The operation begins in the tower basin where the cooled water is pumped out into the facility and utilized for cooling the equipment on the tower system.

As the equipment is cooled, the water picks up the heat and returns to the top of the cooling tower. The hot water is distributed onto a hot deck or through the sprayer nozzles that evenly distribute it over the tower fill media. The tower fill media is designed to increase surface area, as well as contact time between air and water.

This enhances evaporation and allows further cooling of the tower water. The water then falls into the tower basin where it is then pumped back into the facility continuing to cool the equipment.

Cooling Tower Cleaning Case Studies

Flow rate in cooling tower blowdown line restricted to less than 30% capacity. Piping meanders for over 5,000 feet, preventing mechanical cleaning and circulation.