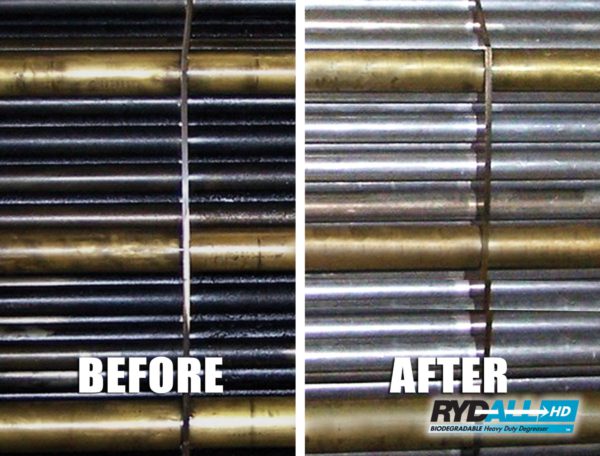

Product Description

RYDALL HD Heavy-Duty Degreaser is our new biodegradable, non-hazardous, citrus-based, heavy-duty industrial degreaser. It is a water-soluble, non-butyl, non-phosphate, non-corrosive, emulsifier. This innovative product is used specifically on hydrocarbon-based derivatives that are found on the oil or process side of the equipment, simply by circulating through the equipment.

RYDALL HD HEAVY-DUTY INDUSTRIAL DEGREASER APPLICATIONS

- Heat exchangers

- Rig wash

- Tube bundles

- Oil coolers

- and other hydrocarbon contaminated equipment.

This equipment can be found in numerous industries including:

- Petrochemical

- Pharmaceutical

- Pulp and paper

- Power

- Plastics

- or similar industries

RYDALL HD HEAVY-DUTY DEGREASER CLEANING

The way in which RYDALL HD works is that the chemical composition of the cleaning solution demulsifies the light carbons with non-aggressive ingredients. It breaks the oil bond that holds together all of the different hydrocarbons that comprise the fouling residue. Our highly concentrated RYDALL HD is utilized in a diluted format and is typically heated to between 140-160ºF (60-71ºC), but may also be used at ambient temperatures. As such, the water component becomes an integral part of the RYDALL HD flushing the demulsified particles off of the fouled surfaces. The heavier hydrocarbons (tars, cokes, varnishes, etc.) are washed out as well, even if they are not completely emulsified. This is because the underlying principle of our chemistry is to simply break the oil bonds that are holding all of the particles together to release them so they can be easily removed by the flowing solution. Thus, restoring flow rates and volumes, ultimately returning your equipment back to “as new” or peak operating efficiency.

Although most every RYDALL HD application is slightly different, and technically covered under a case-by-case basis, the fundamentals are essentially the same. Use at 25-50% dilution for circulation applications, pumping in the bottom, up, and through the top of the equipment for the prescribed amount of hours (typically 4-6 hours). For surface and pressure washer applied applications, dilute at 10-50% depending on the severity of the surface contamination.