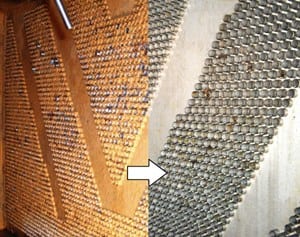

Heavy mineral deposits within a main turbine condenser at a combined cycle power plant were the culprits in significant heat transfer loss. The turbine consisted of 16,424 tubes (42 feet in length with 54-inch diameter). The client put RYDLYME to the test against sulfuric acid to see which one could break through the severe buildup and restore the system’s appropriate level of heat transfer.

RYDLYME approach

- 6,930 gallons circulated via 4” pump (800-900gpm) and back into a 21,000-gallon baker tank for 24 hours.

RYDLYME results

- Mineral deposits removed restoring the proper level of heat transfer.

- Cleaning was conducted during planned outage; RYDLYME was tested against sulfuric acid (4,500 gallons injected at 10gpm); sulfuric acid produced minimal results.