Boiler Descaling

How Often Should I Descale a Boiler?

Boiler manufacturers, industrial cleaning companies, and industry organizations have published standards that recommend the frequency for boiler cleanings. Most standards use the deposit weight density from a tube sample to decide when a boiler should be chemically cleaned. You should confirm that a consistent method is used when comparing results over time.

Some boilers can take a great deal of abuse and inattention and still function at competent levels. They may even have davited and hinged doors to easily expose the tubes for inspection and cleaning. Regardless of the type and design of your boiler, the deposits should be monitored by visual inspection, tube sampling, or other methods.

Things to Consider Before Descaling a Boiler

There are many things you need to keep in mind before descaling a boiler. The questions below should help you gather the information you need before moving to the actual descaling process.

- Type and design of boiler; low temperature hot water, high temperature hot water, low pressure steam or high pressure steam?

- Size of the boiler can be obtained from the nameplate or other documentation.

- What is the boiler used for? Heating or process (heat exchanger)?

- Age of boiler?

- The characteristics of the deposits and deposit analysis.

- Thickness of deposit; thickest area, thinnest area, average?

- Date last cleaned, if ever?

- Has any boiler feed-water treatment been used?

- Boiler history?

- What is the boiler’s water capacity?

- Compatibility of the cleaning solvent with the metallurgy of the system.

- Ease of the cleaning application.

- Method of spent solvent disposal.

- Cost of cleaning method.

- Any tubes or sections leaking now? If so, they should be fixed before cleaning.

Basic Boiler Descaling Procedure

Note: The following steps are for reference only. Every boiler is different and may require certain steps not included in the general procedure list below.

- Shut down the boiler.

- Blow down the unit with pressure still on.

- Drain and flush the unit.

- Close the steam valve.

- Add descaler and follow any steps provided by the descaler manufacturer.

- Circulate through the drain or low point and return from the pressure relief valve or high point of the boiler back to a vented container.

- Circulate for 4-8 hours depending on volume.

- Open steam valve.

- Drain, flush, refill, and start up.

Some descalers may require additional steps not listed. Professional assistance may be available; make sure to call the manufacturer of your descaler if you need assistance.

Chemical Descaler Hazardous Material Precautions

If you are using a descaler that is not biodegradable and requires special handling, you may have to take some of the following precautions into account:

- “Hazard Communications Standard” including SDS (safety data sheet) information

- “Confined Space Entry” Permits

- Parking Permits; to prevent blocked alleyways, and driveways

- Lockout & Tagout Procedures

- Contractor’s waste stream generator, hauling and disposal site permits

- “Sudden & Accidental Pollution” insurance

- DOT regulations

- EPA regulations

- High temperature solutions

- Installation of heaters, piping, valves, pumps, neutralizers, etc.

- Safe and proper drainage/disposal

- Other plant safety measures

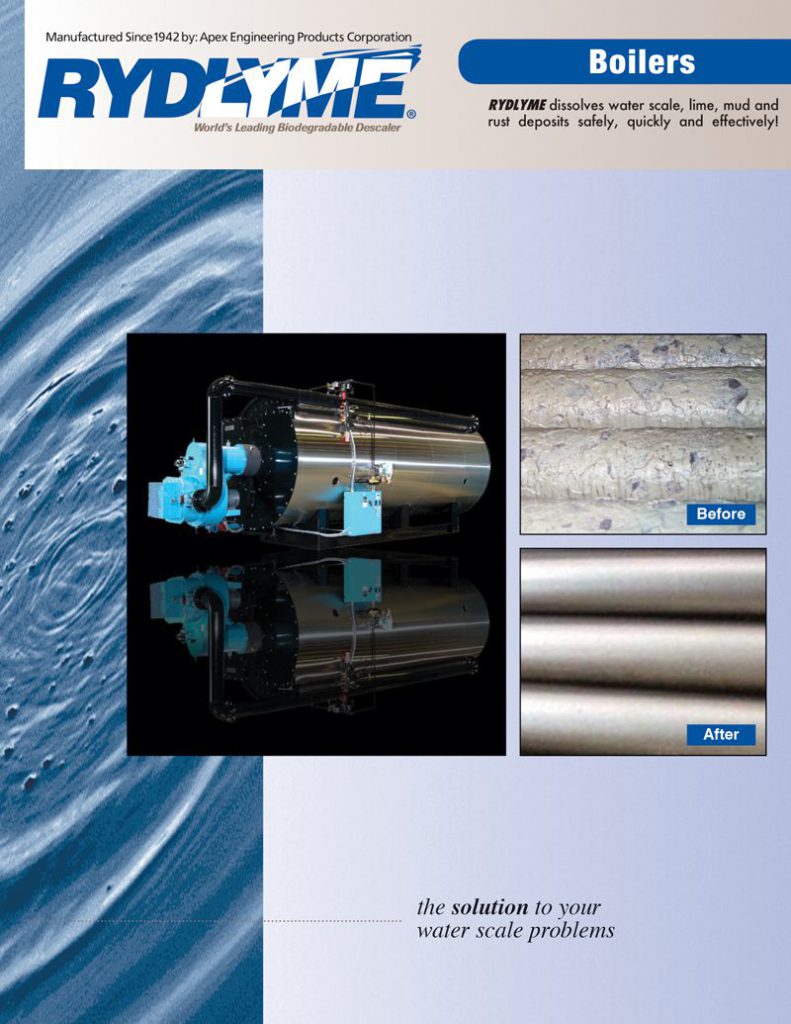

RYDLYME The World’s Leading Biodegradable Descaler

For additional details regarding the specifications of RYDLYME, please visit our Technical Data page or contact the technical department at APEX Engineering Products at 630-820-8888 or on our toll free number 800-451-6291.