COMPRESSED AIR COOLER CLEANING

A Western Steel Mill was facing very high temperatures on three of their 450 HP Trane centrifugal air compressors. The culprit was water scale deposit covering the surface area of the cooler’s tubes. Fortunately, the client found a solution in the biodegradable descaler, RYDLYME. Utilizing 35 gallons of RYDLYME, the descaler was circulated for 4 hours via a 350 GPM pump using flexible hoses and camlock adapters.

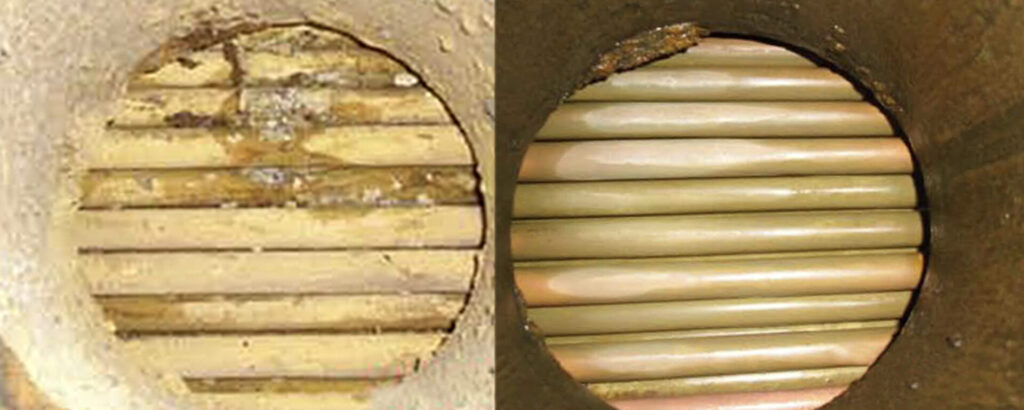

The personnel were extremely impressed with the RYDLYME cleaning results! After the cleaning, the cooler tubes were inspected and looked brand new. RYDLYME was able to dissolve all water scale from the tubes as well as drastically reduce the temperatures. Personnel reported a 30° temperature drop after the RYDLYME cleaning. ‘‘Although only 35 gallons were utilized, the improvement was significant due to densely packed tubes and tendency for water channeling’’ – Plant Engineer.