How to Descale a Heat Exchanger with RYDLYME

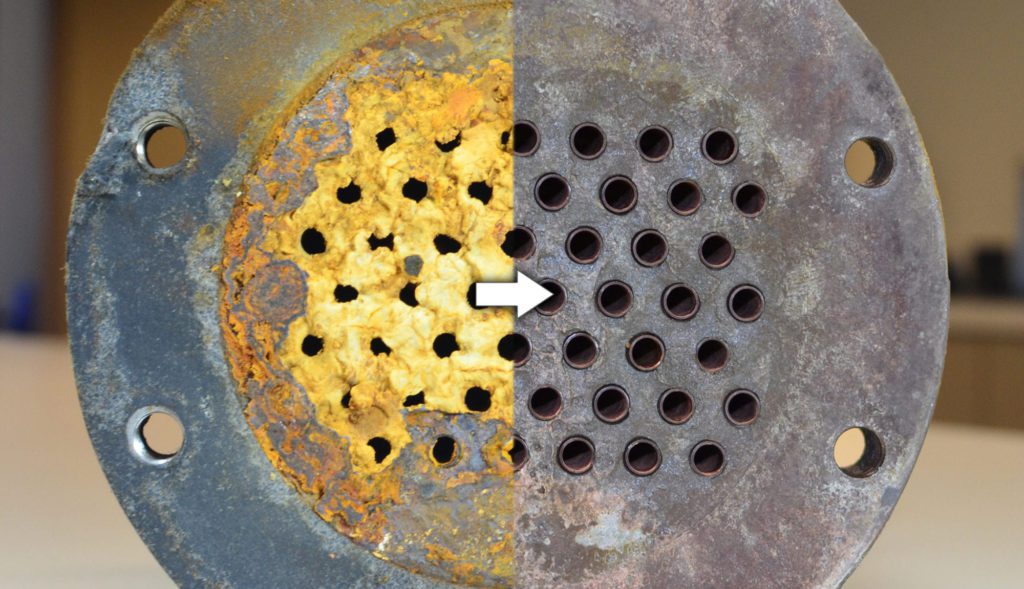

RYDLYME descaler is the perfect tool to descale your heat exchanger and gain back the efficiency that was robbed from deposits! Calcium, rust, limescale, and other harsh mineral deposits don’t stand a chance with RYDLYME biodegradable descaler.

To obtain the quantity of RYDLYME descaler needed to clean your heat exchanger, you will need to know the diameter and length first. Once you have that information, please refer to the chart for the quantity and circulation time. The volume given in the reference chart depicts a 50% concentration, therefore the same amount of water will be required to flood the unit and circulate the solution.

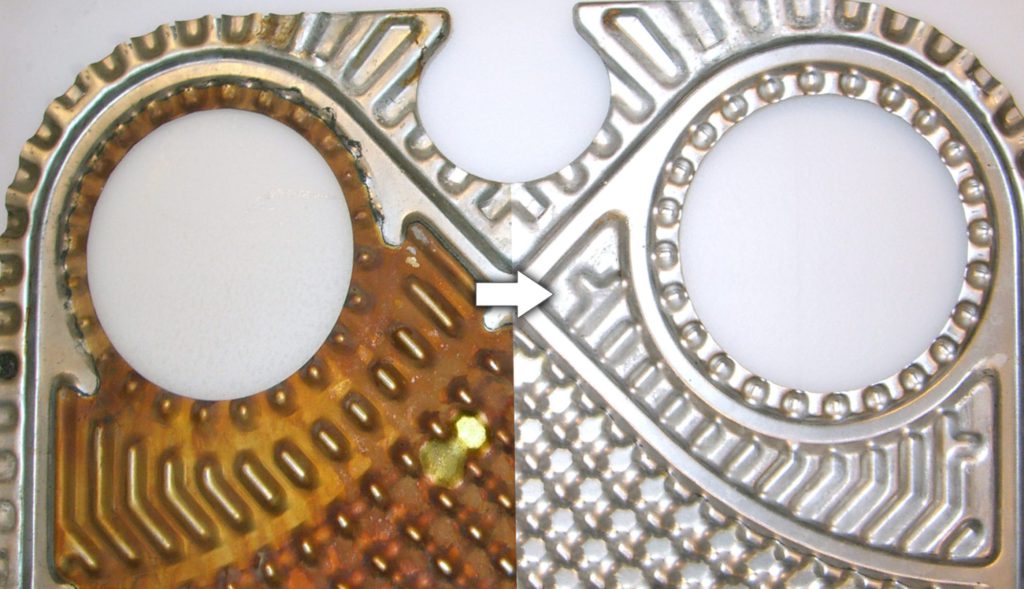

If you’re cleaning a plate and frame, please consult the formula for figuring your volumes in the two boxes below. When isolating the water side of the unit for cleaning, an additional RYDLYME descaler may be necessary if the isolation valves are located further than one foot from the actual supply and return ports of the exchanger. To account for this added volume, add in the piping volume from the exchanger to the valves to ensure an adequate amount of solution.

Why Should You use RYDLYME Descaler when Cleaning a Heat Exchanger?

RYDLYME descaler is the perfect tool for dissolving these deposits that rob efficiency and dramatically increase your fuel consumption. An annual RYDLYME descaler cleaning will dissolve the calcium, magnesium, rust, and other deposits into solution without harming the metallurgy or components within your heat exchanger. RYDLYME descaler is non-hazardous to the personnel who perform the cleaning and disposal is simple upon completion of the cleaning; as RYDLYME descaler is biodegradable.

Our biodegradable and innovative descaler, RYDLYME, is the universal product of choice for heat exchanger scale removal. Besides avoiding heat exchanger failures, with RYDLYME you regain original design heat output, efficiency, and reliability!

RYDLYME Features:

- Biodegradable

- Dissolves 2.2 lbs of scale per gallon of RYDLYME

- NSF/ANSI 60 certified

- Non-hazardous, non-corrosive and safe for personnel

Basic Heat Exchanger Descaling Procedure:

- Isolate and drain the water side of the exchanger to be cleaned.

- Place a 1” ball valve between the isolation valves and the heat exchanger on both the supply and return.

- Attach the RYDLYME pump and hoses so the RYDLYME will be pumped in the bottom or supply, and back out the top or return.

- Begin pumping all the required RYDLYME into the exchanger. Once that is accomplished, begin to add water to complete the circulation. Please note: The calcium deposit will take up volume within the heat exchanger, so you will not be able to add the same amount of water in the beginning.

- Continue circulating the solution for the recommended amount of time. As the circulation progresses and the product dissolves the deposits inside the unit, the volume will increase. To account for the increase in volume, please add water to the circulation vessel, as needed. If you begin adding a lot of water, please be aware, it is possible there is a leak in the system.

- It is a good idea to periodically check the effectiveness of the solution while circulation is in progress. This can be accomplished by utilizing a pH meter and as long as the solution retains a low pH, the product is active. Should the circulating solution reach a pH of 5.5 to 7.0 before the recommended time is up, you will need to add more RYDLYME and possibly extend the circulation time..

- Upon completion of the recommended circulation time, the solution may be purged to a normal sewer and flushed with water. This process is completed by placing the return hose in the drain and adding water to the circulation container until the discharge line runs clear.

- The unit is ready to be returned to service.

- The same instructions may be used for plate and frame-type heat exchangers. For volumes, please follow the noted formula.

Please note: If your situation dictates that you cannot take your heat exchanger off-line, please contact the manufacturer for online cleaning instructions.

For more detailed instructions, call Apex Engineering Products today for a free quote at 630-820-8888 or download our heat exchanger cleaning brochure here!