Spring Cleaning for Facilities

Tough on scale, gentle on equipment – Get your industrial facility ready for peak performance this spring with a comprehensive cleaning program. Our approach centers around RYDLYME Descaler, the industry-leading biodegradable descaling solution, complemented by RYDALL CC coil cleaner and RYDALL MP degreaser. This trio tackles the toughest mineral scale, biological fouling, and greasy build-up on your large industrial facility equipment, restoring efficiency and reliability after a long winter. By descaling and cleaning critical systems (from cooling towers to condenser tubes and beyond), you’ll ensure optimal operation when the heat of summer arrives.

Product Highlights

Our spring cleaning solution features a suite of Apex Engineering Products designed to revitalize your equipment. Below are the key products and tools that make spring cleaning for facilities safe, fast, and effective:

RYDLYME Descaler

A cooling tower basin component before (left) and after (right) cleaning with RYDLYME descaler. Thick mineral deposits and scale are dissolved into liquid solution, leaving metal surfaces clean and unobstructed. RYDLYME Descaler is a powerful biodegradable industrial descaler formulated to dissolve tough mineral deposits like water scale, limescale, rust, and even struvite. It is non-corrosive, non-hazardous, and safe for use on metals, plastics, and other materials within your systems. RYDLYME can be circulated through equipment in place (often without disassembly or downtime) to chemically dissolve scale from condenser tubes, evaporative condensers, heat exchangers, cooling towers, boilers, and any water-contacted equipment. Most descaling jobs can be completed in a few hours, making RYDLYME an efficient alternative to labor-intensive mechanical cleaning.

RYDALL CC Coil Cleaner

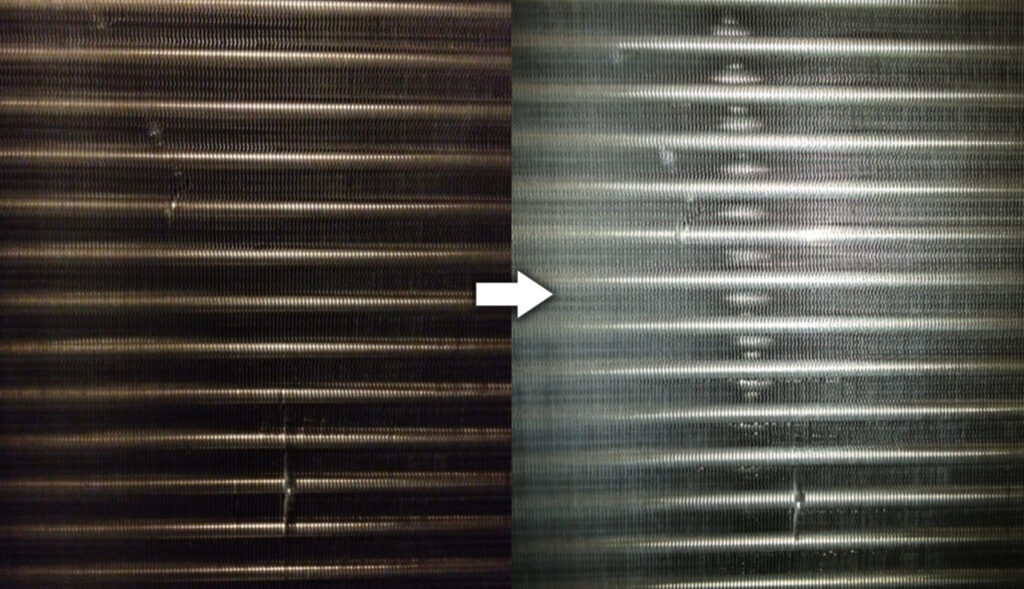

An HVAC finned coil before (left) and after (right) treatment with RYDALL CC coil cleaner. Dirt, dust, and oxidation are removed, brightening the aluminum fins for like-new heat transfer performance. RYDALL CC is a non-corrosive coil cleaning solution specifically designed for HVAC and refrigeration coils. It safely cleans and brightens air-cooled condenser coils, evaporator coils, air handler units, and other finned heat exchange surfaces. RYDALL CC penetrates deep into coil fins to remove dirt, grime, and biological growth that reduce airflow and cooling efficiency. By cleaning coils with RYDALL CC as part of your spring maintenance, you improve heat transfer, enhance indoor air quality, and ensure your HVAC systems operate at peak efficiency during the summer months.

RYDALL MP Multi Purpose Degreaser

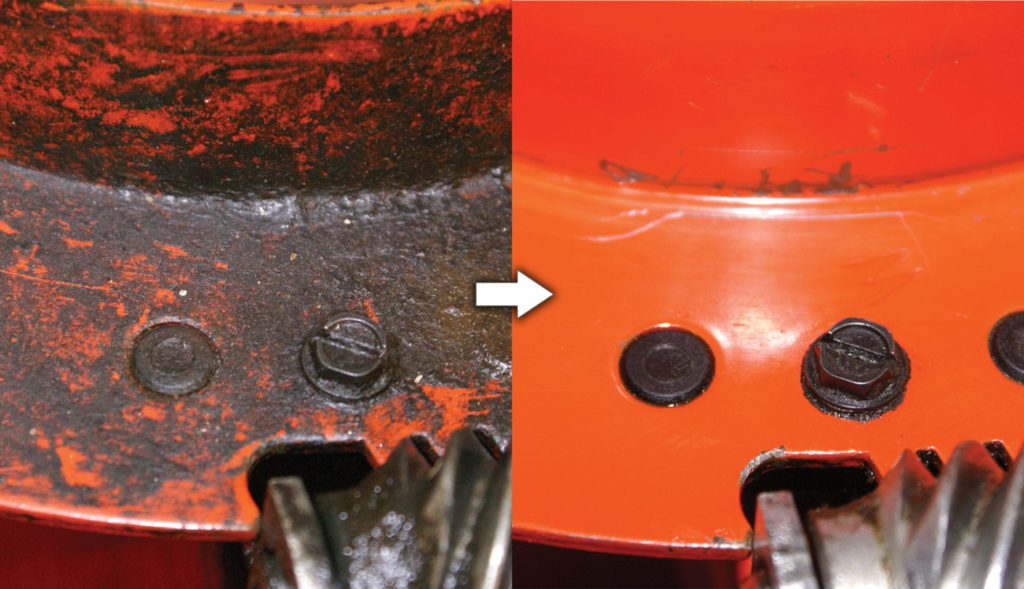

A machine part caked with grease and grime (left) is restored to a clean, paint-bright surface (right) after using RYDALL MP multi-purpose degreaser. RYDALL MP is a versatile multi-purpose degreaser that tackles oil, grease, and grime on virtually any surface. This strong yet biodegradable cleaner can be used on industrial equipment, machinery, floors, walls, and more. RYDALL MP‘s non-solvent, alkaline formulation cuts through heavy organic deposits quickly – simply spray on and watch stubborn grease loosen within seconds. It’s safe for use in industrial and commercial facilities (NSF A1 certified for food processing areas) and may be diluted to suit different cleaning applications. Including RYDALL MP in your spring cleaning means no greasy residue is left behind – just clean, safe surfaces free of slip hazards and operational buildup.

Industrial Descaling Systems

In addition to chemical solutions, Apex provides industrial descaling systems (clean-in-place pump systems) to make the descaling process even easier. These portable pumping carts (such as the 10CIP unit) are specifically designed to circulate RYDLYME through your equipment. With features like durable hoses, tanks, and flow control, an industrial descaling system allows one person to safely connect to large equipment and perform a thorough cleaning loop. This means you can descale condensers, chillers, and heat exchangers in place without manual scrubbing. The result is a faster, more uniform descaling with minimal effort – perfect for spring maintenance when multiple units may need attention.

Applications

Wondering which equipment will benefit from a spring cleaning? Our RYDLYME-based descaling and RYDALL cleaning solutions are ideal for a broad range of industrial applications common in HVAC and process industries:

-

Condenser Tubes & Chillers: Descaling condenser tubes in chillers and larger AC systems restores heat transfer and lowers energy consumption. RYDLYME dissolves the insulating scale deposits inside tube bundles, allowing chillers and condensers to run more efficiently and reliably.

-

Evaporative Condensers & Cooling Towers: Using RYDLYME for descaling evaporative condensers, cooling towers, and fluid coolers removes mineral scale that clogs fills, spray nozzles, and basin surfaces. Clearing these deposits improves water circulation and airflow, which directly boosts cooling capacity and prevents overheating in hot weather.

-

Heat Exchangers & Boilers: RYDLYME effectively cleans shell-and-tube heat exchangers, plate heat exchangers, and boiler tubes by dissolving scale and rust that impede thermal exchange. Regular descaling of heat exchangers and steam boilers in the spring ensures your process heat systems and building heating equipment run at optimal efficiency with restored capacity.

-

HVAC Coils & Air Handlers: Dirty evaporator and condenser coils in rooftop units, chillers, or air handling units are addressed with RYDALL CC coil cleaner. Removing dust, pollen, and grime from coils improves HVAC system performance, increases airflow, and helps maintain healthy indoor air quality.

-

Pipes, Pumps & Other Equipment: Any other large industrial facility equipment that comes in contact with water (or oil) can be cleaned. This includes piping systems (to remove scale buildup or struvite in wastewater lines), cooling jackets, pump impellers, cooling tower basins, and more. RYDLYME and RYDALL MP together ensure that all surfaces – from water-side to oil-side – are free of foulants and deposits.

In short, spring cleaning for facilities covers virtually every piece of equipment that accumulates deposits or grime. By addressing these areas now, you set the stage for trouble-free operation during the demanding months ahead.

Key Industries We Serve

Our cleaning solutions are trusted across numerous industries. Some key sectors that especially benefit from spring descaling and cleaning include:

-

HVAC & Building Facilities: Commercial buildings, hospitals, universities, and other facilities with large HVAC systems use RYDLYME and RYDALL to keep chillers, cooling towers, and boilers in top shape. Spring cleaning these systems results in lower HVAC energy bills and reliable cooling throughout the summer. (For example, a university physical plant used RYDLYME to dissolve scale in their boilers and chillers, restoring efficiency and avoiding unplanned downtime.)

-

Pulp & Paper Mills: Scaling is a constant challenge in pulp and paper operations due to heavy water usage. Mills use RYDLYME to clean evaporators, digesters, heat exchangers, and process lines plagued by scale deposits. Removing these deposits in the spring helps prevent flow restrictions and production slowdowns. In one case, a paper mill was able to increase pulp production after RYDLYME eliminated severe calcium buildup in a critical heat exchanger.

-

Data Centers: Data centers rely on efficient cooling infrastructure (like CRAH units, chillers, and heat exchangers) to protect servers. RYDLYME descaler is used to remove scale from cooling tower loops and plate-and-frame heat exchangers, ensuring maximum heat transfer. Meanwhile, RYDALL CC keeps AC coils clean for proper air conditioning. Regular maintenance each spring with these products helps data centers avoid thermal shutdowns and maintain 24/7 uptime.

-

Wastewater Treatment Facilities: Wastewater plants frequently combat mineral and biological deposits. RYDLYME is especially effective for dissolving struvite and scale in pipes, clarifiers, and heat exchangers at wastewater treatment facilities. Paired with RYDALL MP (for degreasing pumps, clarifier mechanisms, etc.), it keeps the plant equipment clean and operational. Spring descaling in wastewater systems can significantly reduce blockages, odors, and energy draw on pumps.

No matter the industry, the combination of RYDLYME descaler with targeted cleaners like RYDALL CC and MP provides a one-stop solution for facility-wide cleaning.

How It Works

Our spring cleaning program is straightforward and designed to minimize downtime. Here’s how you can implement it step by step:

-

-

Assess & Prepare: First, identify the equipment that needs cleaning (cooling towers, condensers, boilers, coils, etc.) and isolate or shut it down as required. Ensure you have the appropriate Apex cleaning products on hand. For safety, personnel wear proper PPE (gloves, goggles) during the cleaning process.

-

Circulate RYDLYME Descaler: Connect an industrial descaling system pump (or existing circulation pump) to the scaled equipment. Mix the required amount of RYDLYME with water (typically a 20–50% solution) and circulate it through the system. Descaling takes anywhere from 2 to 6 hours on average. You’ll notice bubbling as RYDLYME dissolves the scale. It penetrates and loosens deposits even in tight spaces like condenser tubes and plate heat exchangers. (In many cases, equipment can even remain operational while RYDLYME works, or be brought online immediately after without cool-down time.)

-

Rinse & Inspect: After the circulation period, flush the system with fresh water to remove all dissolved solids and any remaining solution. Inspect the surfaces – you should see bare metal where heavy scale once existed. Any stubborn deposits might require a second pass, but generally RYDLYME will have cleared the majority in one go.

-

Clean Coils & Surfaces: Next, spray RYDALL CC onto dirty coils and fin surfaces using a low-pressure sprayer or foaming applicator. Let it sit for 5–10 minutes to penetrate dirt and oxidation, then rinse with water. The coils will come out bright and clean. At the same time, use RYDALL MP degreaser on grease-laden components: spray, allow a short dwell time, then wipe or rinse off. Stubborn grime will lift away with ease.

-

Finalize & Restart: With scale removed and coils/surfaces cleaned, return the equipment to service. The entire spring cleaning procedure can often be completed in a single maintenance day. Immediately, you’ll benefit from improved heat exchange efficiency, higher flow rates, and cleaner air output. Even a thin layer of scale (as little as 1/16 inch) can reduce equipment efficiency by around 10%, so removing these deposits has a significant impact. Your systems are now ready to handle peak loads more efficiently and reliably.

-

Following these steps annually (or as needed) will extend the lifespan of your equipment, maintain design performance, and reduce the risk of emergency repairs during critical operation periods.

Benefits of Spring Descaling & Cleaning

Performing a thorough cleaning of your facility’s equipment delivers numerous tangible benefits:

-

-

-

Restore Energy Efficiency: Removing scale and fouling restores lost heat transfer efficiency, meaning chillers, boilers, and cooling towers don’t have to work as hard to achieve the same output. Even small amounts of scale or dirt can drastically increase energy consumption. Clean equipment uses less power and saves on operating costs immediately.

-

Prevent Costly Downtime: Proactive descaling and cleaning help prevent unexpected failures. By addressing deposits and grime now, you reduce the chance of clogs, overheating, or pressure drops that could cause unplanned shutdowns during peak production or the hottest weather. This preventive maintenance ensures continuous, reliable operations when it matters most.

-

Extend Equipment Life: Clean systems experience less corrosion, stress, and vibration. Scale, for example, can cause hot spots and under-deposit corrosion in boilers or chillers. By eliminating these deposits, you protect your equipment from damage. Well-maintained coils and machinery also face less strain. The result is a longer useful life for expensive assets and deferred capital replacement costs.

-

Improve Performance & Output: When heat exchangers and condensers are free of insulating scale, they exchange heat as designed – often restoring lost capacity. Your cooling towers can achieve proper temperature drop, and process equipment can reach intended production rates. In HVAC systems, clean coils provide better cooling and airflow, improving comfort and indoor air quality for occupants.

-

Environmental & Safety Gains: Using biodegradable, non-hazardous cleaners like RYDLYME, RYDALL CC, and RYDALL MP means you’re maintaining safety for personnel and the environment. There are no harsh fumes or risky acids required. Additionally, running equipment at peak efficiency after cleaning reduces fuel and electricity usage, which is environmentally friendly. Plus, removing grease and slime enhances workplace safety by eliminating slip hazards and ensuring proper equipment function (e.g., motors don’t overheat due to grime).

-

-

Each of these benefits contributes to a more efficient and cost-effective facility. By scheduling a spring cleaning, you’re investing in smooth operations for the seasons ahead.

Success Stories

Nothing speaks louder than real-world results. Here are a few brief case studies showcasing the impact of our descaling and cleaning solutions:

-

-

-

-

University Boiler & Chiller Overhaul: A Midwestern university was experiencing poor performance in their central heating and cooling plant. Scale buildup in a large boiler and closed-loop chiller system led to reduced heating output and chiller inefficiency. The maintenance team circulated RYDLYME through the boiler and chiller condenser tubes. After a single cleaning cycle, the boiler tubes were restored to bare metal and the chiller’s condenser approach temperature improved markedly. The school reported energy savings and has scheduled RYDLYME descaling as a regular maintenance step each spring.

-

Data Center Cooling Tower Descaling: A data center in a hot climate noticed rising server room temperatures due to a fouled cooling tower and plate heat exchanger. During spring maintenance, they added RYDLYME to the cooling tower basin and circulated it through the tower and exchanger. The cooling tower fill and heat exchanger plates were descaled without shutdown. Post-cleaning, the cooling system’s efficiency rebounded – chiller head pressure dropped to normal and the facility avoided what could have been a costly emergency cooling outage. (Watch the process in our cooling tower cleaning video to see RYDLYME in action.)

-

Pulp & Paper Mill Scale Removal: A pulp & paper mill in the Midwest faced a production slowdown due to severe scale in a black liquor evaporator and several process heat exchangers. The deposits were restricting flow and heat transfer. The mill’s maintenance crew performed a RYDLYME cleaning on these units during a planned spring outage. The result was a dramatic increase in evaporator efficiency and throughput – allowing the mill to meet its production targets in the following quarter. The plant managers noted that mechanical cleaning would have taken much longer and not achieved the same level of deposit removal.

-

Wastewater Plant Equipment Cleaning: At a municipal wastewater treatment facility, operators used RYDLYME to dissolve struvite buildup in pipes and a heat exchanger used for sludge heating. The success of the spring cleaning led the facility to incorporate RYDLYME descaling into their standard operating procedures for annual maintenance.

-

-

-

Each of these success stories highlights how RYDLYME descaler and the RYDALL cleaners help facilities avoid problems and achieve measurable improvements. (Visit our Case Studies page for more detailed write-ups and additional examples.)

Ready to Transform Your Facility?

Spring is the perfect time to give your facility a fresh start. If you’re ready to boost efficiency and reliability with RYDLYME and RYDALL, contact us today to get started. Fill out the form below to request a quote or consultation – our team of experts will work with you to tailor a spring cleaning plan for your specific equipment and needs. You can also call us at 630-820-8888 to speak directly with a knowledgeable representative.

Don’t wait until deposits cause a breakdown or inefficiency. Take action now and let Apex Engineering Products help you make “spring cleaning” an annual success for your facility. With proven solutions like RYDLYME Descaler, you’ll reap the rewards of improved performance, lower costs, and peace of mind all year long. Contact us today and experience the Apex Advantage in your facility!